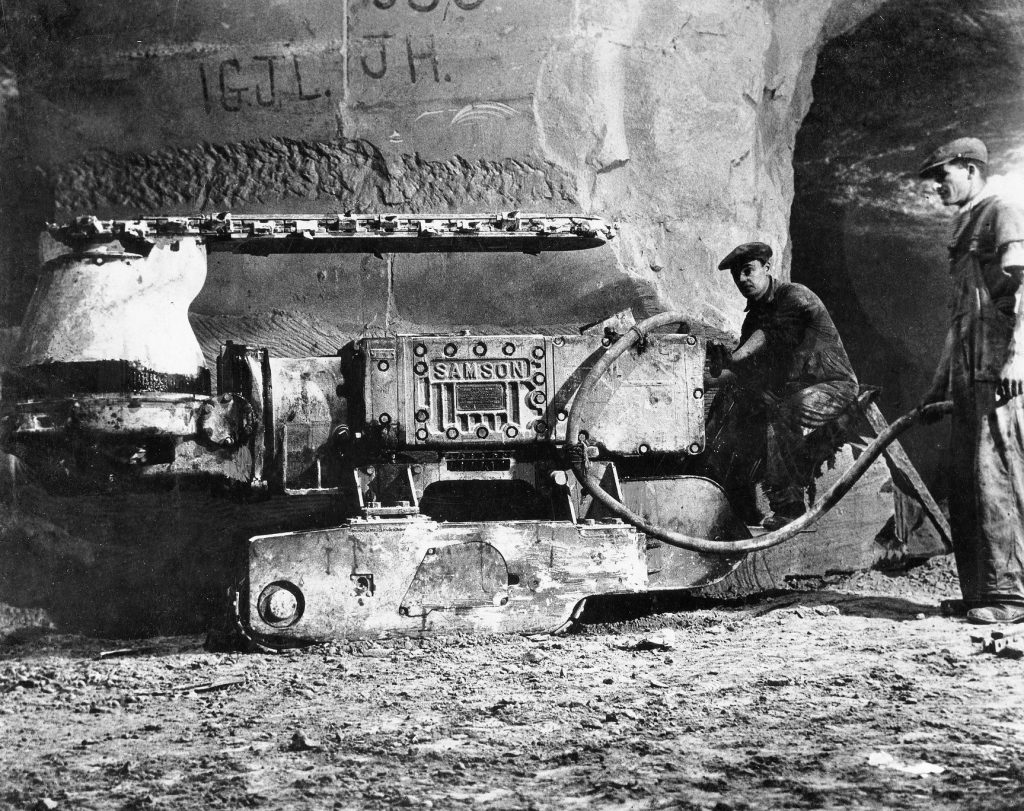

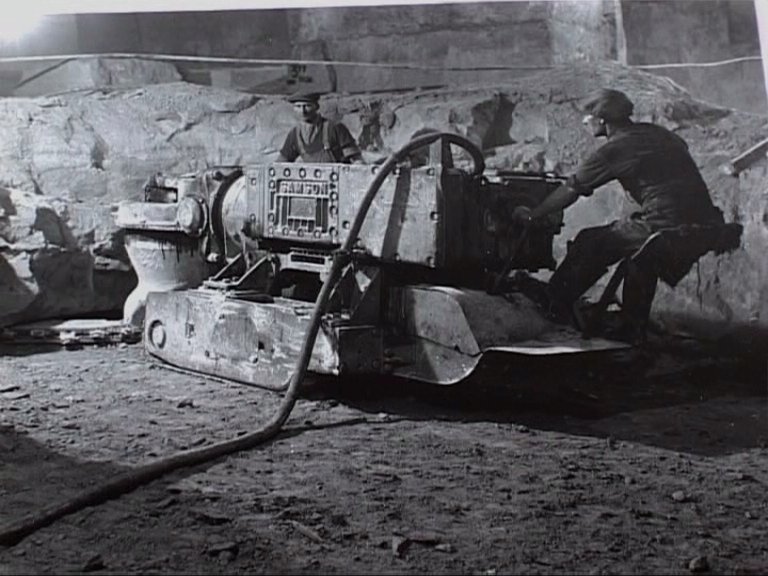

The Samson coal cutters, built by Mavor and Coulson of Glasgow were initially trialed in Tunnel Quarry to mechanise the removal of stone rapidly to enlarge or grade areas needed for conversion to storage facilities. Many of the labourers were from the north of England and the coal fields hence the idea to use these machines arose. It proved a great success and the cutters worked well without much modification.

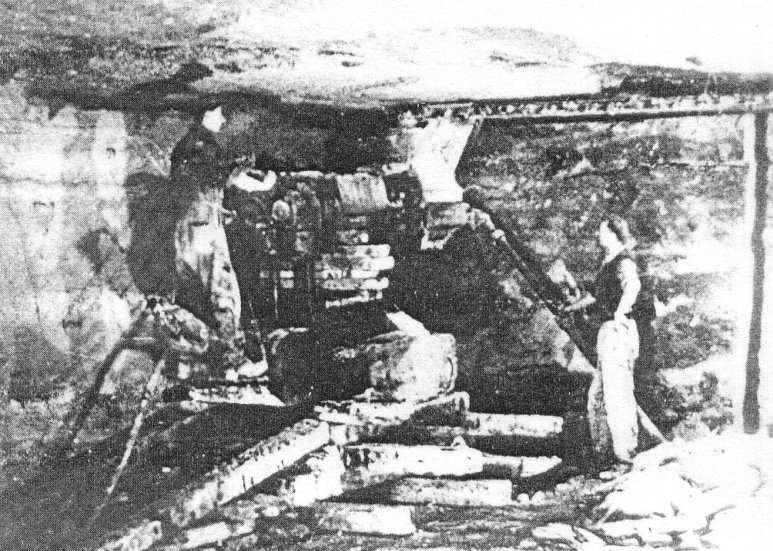

After the war in 1948 at Moor Park Quarry, using the Samson Coal Cutter (by now obsolete at the Coal Board) trials were carried out to see if these machines were suitable for quarrying stone commercially, they were indeed worthwhile, however it could only be used where sound ceilings permitted the wide headings which were needed for the swinging round of the machine. It had a jib which carried a cutter chain and a continuous belt of up to 37 picks, allowing a maximum of 8 ft 6 inch of cut. These picks require regular sharpening. The jib was versatile and the machine could cut horizontally (the picking), vertically (saw cuts) and into the floor (sumping)

The machine moved on its own caterpillar tracks and weighed 7 tons, was very noisy but rapid, being 50 times faster than an expert picker, even allowing for the time taken to set it up to the right height etc All the cuts are 5 inches wide, and therefore there was more wastage of stone compared to the manual method.

In the quarries today it can be seen very obviously if a coal cutter was used in the area, due to the arc in the walls of ceilings made by the rotating head