A typical quarryman’s working life in the 19th century started at the age of 14, even younger prior to the 19th century. Quarrymen were paid piece-work ie. by the amount of work that was done rather than a fixed salary. At 14 the first jobs would have been of a labouring type such as operating cranes or horses with low pay and little skill. It was a very hard life starting work at 6 or 7am and working till 5pm, often at weekends too – 50 hours a week. Many quarrymen walked several miles to work and back, some living in Bath and walking to Corsham.

Engine drivers used to operate steam engines on the surface to winch the blocks of stone up vertical shafts or slope shafts. Only one steam engine is known to have been used underground at Clift Quarry however.

Carpenters were employed making and repairing trolleys, cranes and handles for tools which frequently needed replacing.

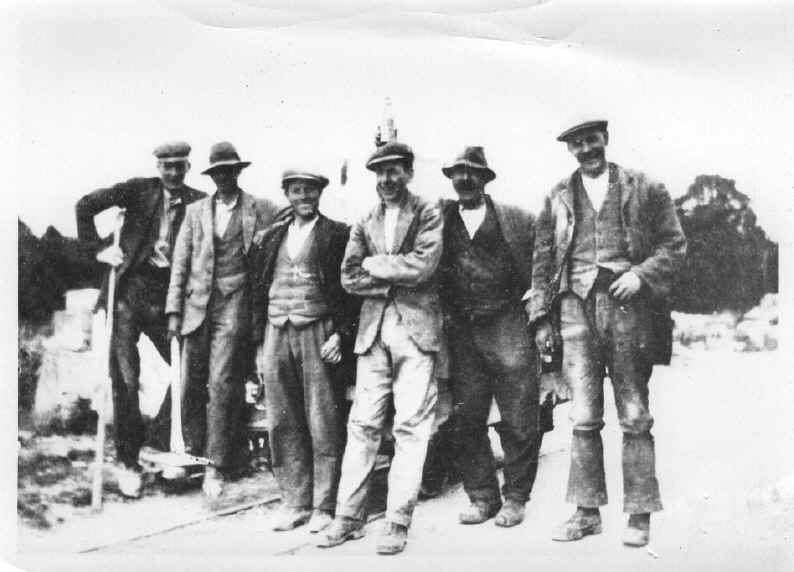

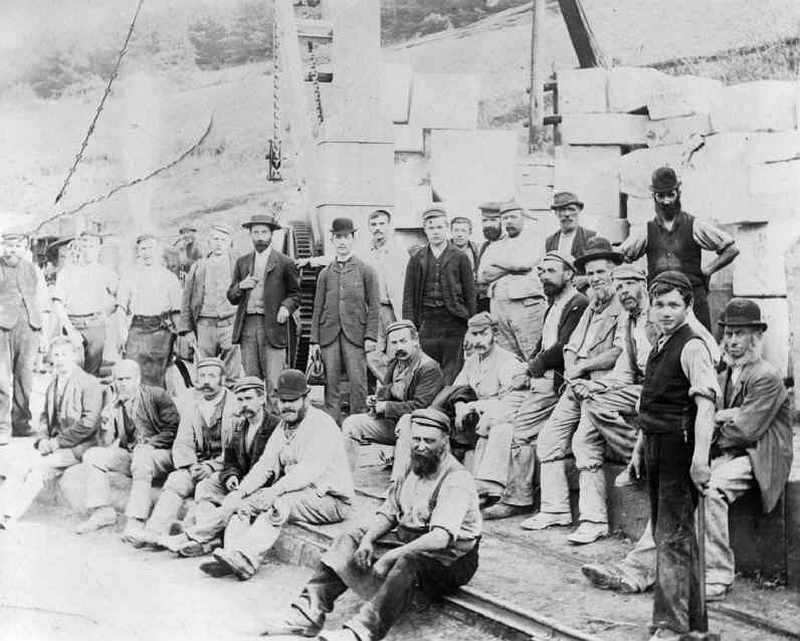

Corsham quarrymen circa 1930

Surveyors were generally not employees of the stone companies but were employed when required to determine the boundaries of the workings underground – quarry leases are always determined by surface boundaries, so it was critical to know where you were in relation to these.

Railmen were employed to lay and remove track as the quarries evolved, when one heading had been worked completely, the track could be re-used elsewhere.

Choppers were men who squared a stone with an axe type implement known as ‘scappling’ this was done underground before the blocks were loaded onto the trolleys – partly to make them easier to transport and partly to leave any waste stone behind rather than in the mason’s yard.

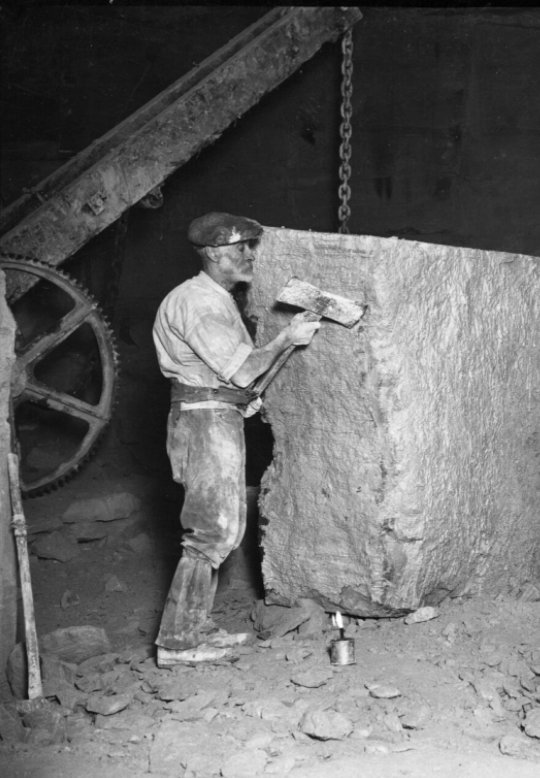

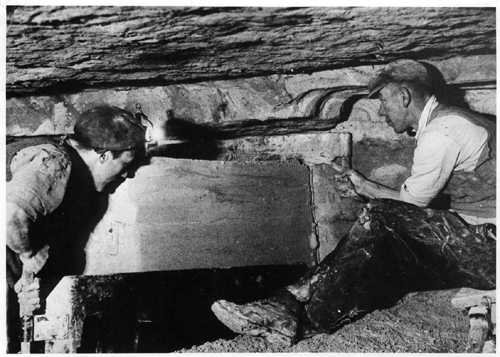

A crane chog hole being cut with a pick

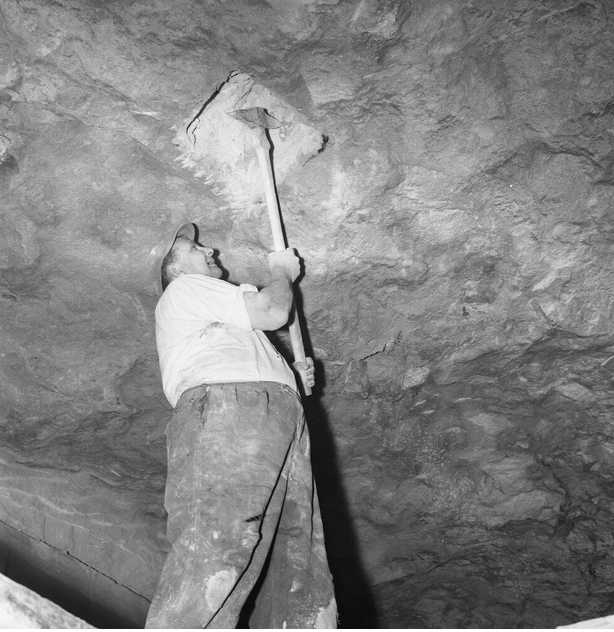

Pickers were men employed to make the first cuts into the working face usually horizontally at ceiling lever using longer handled picks the deeper the cut progressed. Once the maximum depth was reached a sawyer would make a vertical cut downwards to create the ‘sides’ of the block to be removed. The last hand picking was done by Bill Inchly at Park Lane Quarry in the 1950s. In the photo above a chog hole for a crane support is being picked into the ceiling.

Tapstones were men responsible for measuring and checking the quality of the stone quarried so as to calculate payments.

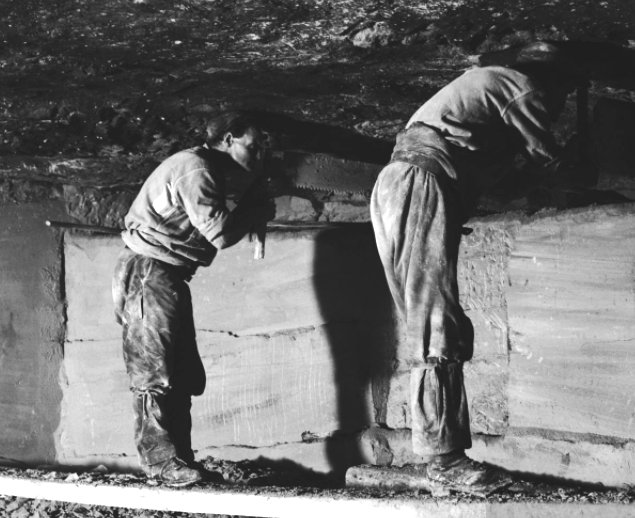

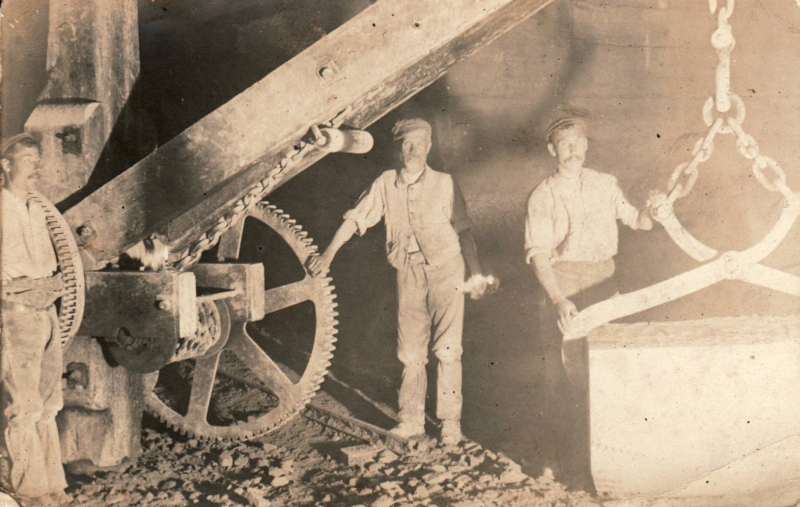

Vertical cuts being sawn in the breach

Sawyers made the vertical cuts in the stone, although it was found that they could gain a larger block in the lower beds if they started the cut at 80 degrees to the ground rather than a perpendicular 90 degrees. This results in the tapered walls and pillars seen today. ranging from 5 feet to 8 feet long, and from 10 to 12 inches in depth; regular sharpening with a triangular Tyzack file eventually converted it into the shallower ‘razzer’ saw necessary for making cuts in the jad. It was possible to saw about fifteen square feet in an hour in the softest stone, thus greatly increasing output compared with the earlier Jadding. Saws were supplied by Spafford & Co of Sheffield and G & T Gray during the 1880s. Most sawyers were generally employed on the surface rather than underground in the masons yards however, they used a traditional one legged stool when cutting with a large saw such as the frig bob.

The back cut being made once the wrist stone had been removed

The Ganger reported to a Foreman and was in charge of a gang working a heading

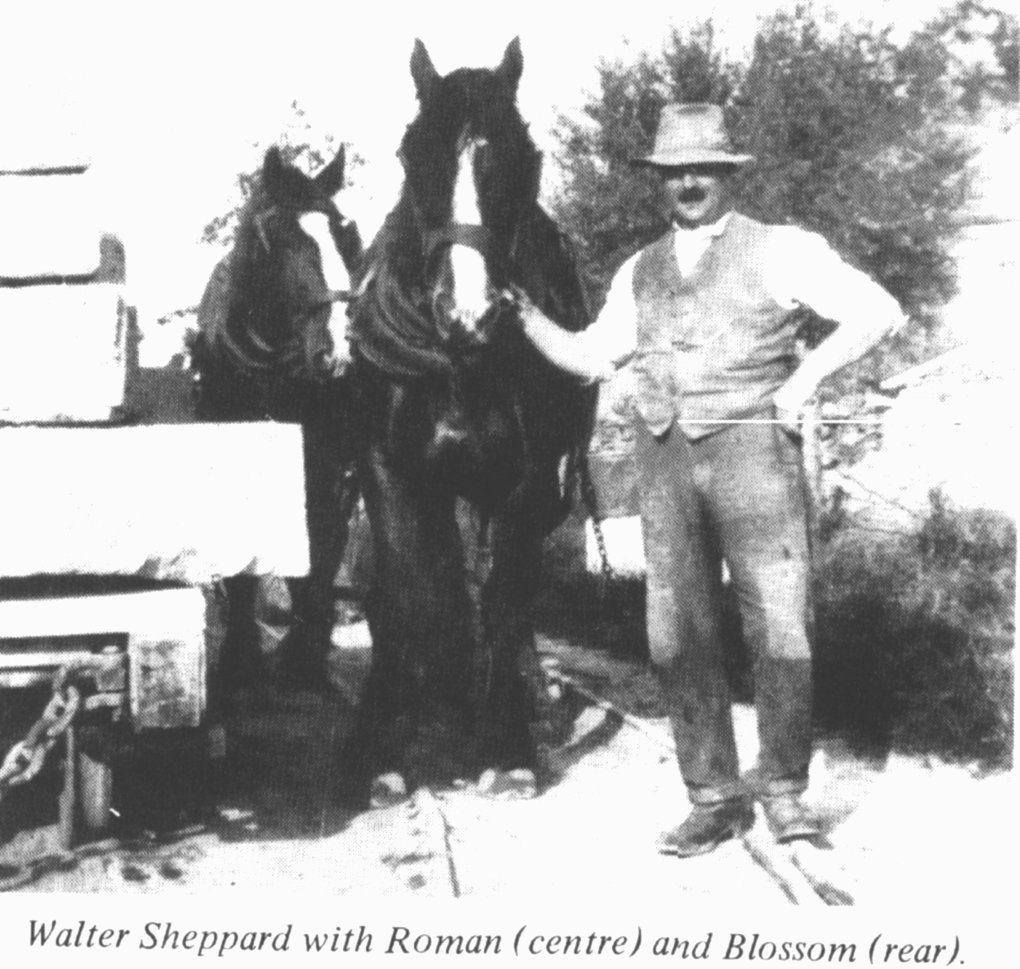

Horse Grooms or Stable Hands although not known by these titles there were many men and boys employed looking afer the horses – the horses were no special breed but a sort of shire cross was best suited for hauling the stone.

Safetymen were later employed by the stone companies and later by the Ministry of Works and Buildings – they were ex quarrymen who understood the stone workings and the dangers involved, when a roof was unstable and how to remedy it.

Clothing usually consisted of an open checked shirt with a neck tie, brown corduroy trousers with a leather strap round the calf to keep plenty of ‘bag’ around the knee to facilitate bending and take some strain when bending over this was also a handy place for a ruler or pencil. The men working underground sometimes made a hat from a rimless bowler for protection from the roof and also to run off the percolating rainwater but a flat cap was more usual, they were never without a hat of some type. The gangers were more smartly dressed sometimes with a waistcoat, collar and tie and a bowler hat or trilby. Hobnail boots known as ‘Holdfast’ were common underground which were waterproof and tough.

Many quarrymen smoked a short clay pipe (nosewarmer) or ‘woodbine’ cigarettes and drank heavily in the evenings – a lot were very religous. Football and Boxing seems to have been the main hobbies of quarrymen – there is plenty of graffiti drawn in the quarries depicting matches and scores. The local pubs were often owned by the quarry owners, sometimes taking the cost of their pints from the wages at the end of the week. The quarrymen sometimes kept a tally of what they owed on the wall of the quarry where they were working.