Quarrymen have always improved their methods to utilise the latest available equipment and invent new quicker ways to quarry stone. It is still a labour intensive process but since the trials of the Samson Coal Cutters of the 1940’s further improvements have been made with mechanisation.

The market leading equipment is now produced by an Italian company Fantini – they manufacture a wide range of chainsaw type machines for different purposes including specifically underground stone quarrying

Health and safety underground is a primary concern nowadays and the roof in the quarries is notoriously unpredictable due to fractures and faults in the stone. The machine above drills into the roof for inserting long bolts, the purpose being to anchor the ceiling bed to the stone above helping prevent any loose rock falling or collapses. The bolts are approximately 1.8m long, 24mm in diameter and secured in place by a chemical adhesive.

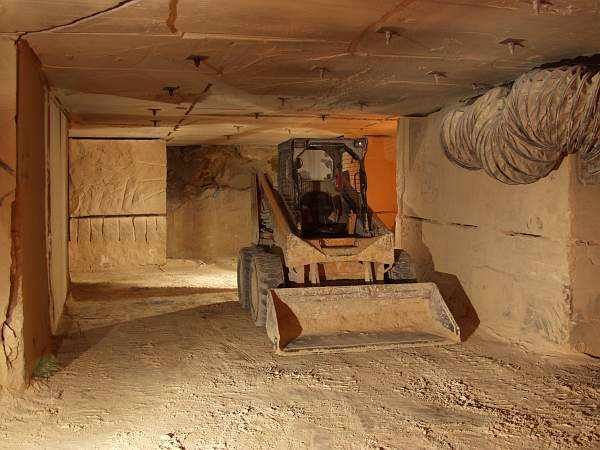

Moving the blocks of stone around is no longer carried out by wagons and horses or tramways – the stone cutter leaves a flat smooth stone floor which is ideal for forklift trucks and wheeled loaders which are operated by one person.

There is more quarry waste produced, simply due to the chainsaw width of cut being far greater than a hand saw, this is easily scooped up with a wheeled loader and dumped in an empty previously quarried gallery.

These are modern winches used for hauling the trolleys loaded with stone up a slope shaft.